DC Electric Arc Furnace Manufacturers, Suppliers

Our company independently designs and manufactures submerged arc furnace, DC electric arc furnace, plasma furnace and high power DC power supply, solid waste, dangerous waste non-toxic treatment equipment equipment.

The mineral and metal that can be smelted: iron, copper, nickel, cobalt, lead, zinc, tin, antimony, bismuth, gold, silver, chromium, molybdenum, magnesium, manganese, tantalum, niobium, platinum, rhodium, palladium, vanadium, titanium, iridium and other metals.

1. High automation degree of PLC control, fast heating rate, stable and reliable production rhythm.

2. In the smelting process, the voltage can be set according to clients’ requirements without shutdown. Different control schemes of constant power, constant current, constant impedance and constant voltage can be realized, convenient and fast.

3. On - load voltage regulation and non - pole current regulation. In the smelting process, the voltage level can be increased or decreased without stopping the machine. The current is accurate to every 1 ampere, increasing or decreasing at will.

4. The electrode can change its polarity at will in the smelting process. Furnace temperature is uniform, effectively solves the uneven furnace temperature defects caused by the anode effect. (patented technology)

5. In the smelting process, it can adjust the length of arc light according to the need without power cut. It can be either submerged arc or open arc smelting, and melt all kinds of materials (arc furnace + ore furnace) with 2 in 1 composite multi-functional use.

6. DC power supply main control board (independent intellectual property rights) has the function of soft start to avoid the phenomenon of a high voltage impact on the boot to destroy the thyristor electrical components. The plate has the function of photoelectric isolation, which can effectively avoid the strong magnetic field in the production site to interfere with the stability of the control circuit in the production process. The board also has the functions of overvoltage, overcurrent, lack of phase and high temperature protection, which can effectively avoid the damage caused by short circuit to the equipment.

7. DC electric furnace electrode center temperature is high with heat concentration, easy to deep buried electrode, furnace bottom is not easy to rise, more suitable for high melting point products smelting.

8. DC ore furnace can save 1 ~ 2 sets of electrode devices than AC arc furnace, and the consumption of graphite electrode can be reduced by 30% ~ 50%. About 6kg of graphite electrode is needed for melting 1t of molten iron in 20t AC arc furnace, while only 3kg of graphite electrode is needed for DC ore furnace with the same capacity.

9. It has the function of detecting the electrode break and automatically adjusting the balance. When the electrode touches the bottom of the furnace, the arc will be generated and the electrode will not continue to run, so as to avoid the accident of breaking the electrode due to the electrode continuing downward movement.

AC arc furnace electrode broken accident site

10. The arc light of DC ore furnace is the center vertical form of heat release, the heat distribution and material melting are uniform. The direct current ore thermal light has a strong electromagnetic stirring effect on the metal melt, which makes the material melt without dead Angle and the product recovery rate is high.

11. The noise is 10 ~ 20 dB lower than that of AC arc furnace.

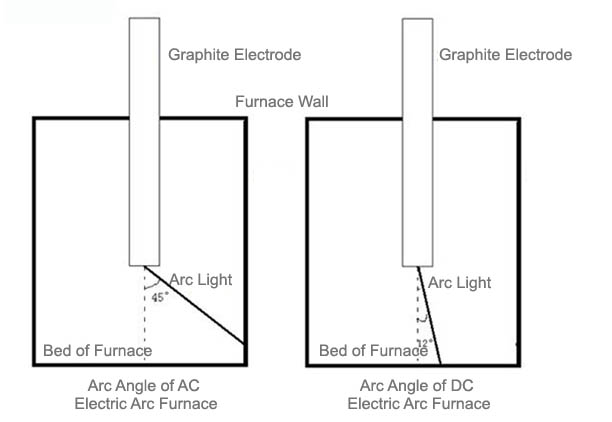

12. Furnace wall refractories have long service life. The Angle between arc light of AC arc furnace and graphite electrode is 45, which is very easy to hit the furnace wall and destroy the refractory material of the furnace wall. The Angle between arc light and graphite electrode of DC mineral furnace is 12, which will not hit the furnace wall and form hot spots on the furnace wall, so it will not destroy the refractory material of the furnace wall.

DC arc furnace is better than AC arc in terms of stability and one-way direction, which is of great benefit to heat transfer of metallurgical process. Theoretical analysis indicates that it is an important technical innovation to replace AC current with DC current. Since the DC current has no zero crossing problem, the arc stability is improved and the interference to the power grid is reduced accordingly. The method of using DC current to smelt metal in DC ore furnace is basically the same as that of AC electric arc furnace. However, because of the high anode heat on the charge side, the electric thermal change efficiency of DC arc is high.

The controlled thyristor static converter is used as the power supply of the DC ore furnace that the AC power supply can be transformed into DC, and by changing the conduction Angle of the thyristor, the smelting current can be controlled continuously and smoothly, and the large current can not exceed the allowable value of the equipment. The three-phase full bridge rectifier circuit can make the rectifier transformer have many simple winding designs and solid and reliable structure. Since the thyristor conduction Angle can only be adjusted when the next thyristor is on, that is, there is a certain time lag. Therefore, a DC reactor DCL needs to be connected in series on the DC side, so that when the arc voltage is reduced instantaneously (short circuit), the dynamic short circuit current will not reach the unacceptable value instantaneously.

1. AC short network is easy to produce skin effect and proximity effect, and the three-phase power is difficult to maintain balance, which leads to the increase of useless work in AC furnace. If the high and low end compensation is not added, the power factor of furnace is only about 0.7~0.8, even if the compensation cost is put into the furnace power factor is only about 0.8~0.9. The DC arc furnace manufactured by our company does not need reactive power compensation device, and the natural power factor is as high as 0.95~0.98.

2. In AC circuit, due to the existence of alternating current, alternating magnetic field in the short network circuit, and then produce eddy current, which causes the short network circuit to heat up, thus losing a part of energy. And the short network circuit in DC circuit will only produce stable magnetic field, without the existence of eddy current, it will not heat up, will not produce eddy current loss waste energy.

3. From the characteristics of the alternating current curve, it is found that the change of alternating current from sine wave to cosine wave 50 Hz, the voltage is over 100 times per second, that is, there are 100 times of arc initiation, arc extinguishing, arc re-initiation, arc re-extinguishing phenomenon, the problem of strong flicker of voltage leads to the instability of AC arc light, harmonic distortion, voltage and current out of phase. Harmonic pollution is produced at the same time, the second and fourth even harmonics coexist with the third, fifth and seventh odd harmonics and seriously exceed the national standard target 5%~27% condition, which complicates the voltage distortion. The DC voltage has zero point characteristics, no polarity change, only weak flash, so the DC arc is more stable than AC arc. In terms of flash intensity, it is only 20% of AC furnace, and the impact on power grid is much smaller than that of AC furnace, and there is no 3, 5, 7, 11, 13 harmonic interference to power grid.

4. Alternating current has skin effect. The internal current distribution of the conductor in the AC circuit is uneven, and the current is concentrated in the "skin" part of the conductor, that is, the current is concentrated in the thin layer on the outer surface of the conductor, and the closer it is to the surface of the conductor, the greater the current density and the smaller the actual current inside the conductor. As a result, the resistance of the conductor increases and the loss power increases. But the DC current has no skin effect, so the short network circuit can pass through more current at the same cross section area, and the power utilization ratio is high and the consumption is less.

If you're interested in our products or have any questions, please let us know. Don't hesitate to contact us!

No. 5 Building, Wenfeng Road, Anyang City,

Henan Province, China

Call us: +83 372 5388851

info@electricarcfurnace.com